Page 107 - Damen Shipyards Group

P. 107

106 DEFENCE & SECURITY | PROJECT POLA WORKING AT DAMEN | KASIA ROMANTOWSKA 107

WORKING AT DAMEN

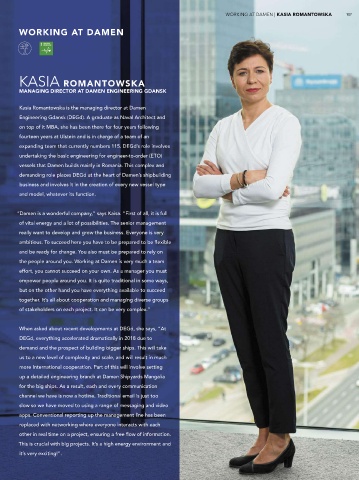

KASIA ROMANTOWSKA

MANAGING DIRECTOR AT DAMEN ENGINEERING GDANSK

Kasia Romantowska is the managing director at Damen

Engineering Gdansk (DEGd). A graduate as Naval Architect and

on top of it MBA, she has been there for four years following

fourteen years at Ulstein and is in charge of a team of an

expanding team that currently numbers 115. DEGd’s role involves

undertaking the basic engineering for engineer-to-order (ETO)

vessels that Damen builds mainly in Romania. This complex and

demanding role places DEGd at the heart of Damen’s shipbuilding

business and involves it in the creation of every new vessel type

and model, whatever its function.

“Damen is a wonderful company,” says Kaisa. “First of all, it is full

of vital energy and a lot of possibilities. The senior management

really want to develop and grow the business. Everyone is very

ambitious. To succeed here you have to be prepared to be fl exible

and be ready for change. You also must be prepared to rely on

Damen, with its long track-record of working scope was to monitor the production there of the over time. Administration practices also underwent

alongside third-party shipyards outside Europe two modules and play an important coordination some modifi cations. Damen has additionally worked the people around you. Working at Damen is very much a team

to build complex vessels, has been transferring role. At the same time, the Mexican team with local suppliers to the project, sharing the effort, you cannot succeed on your own. As a manager you must

knowledge to the Mexican shipbuilding industry via transferred valuable, region-specifi c, operational information and skills necessary to manufacture and

its globally successful Damen Technical Cooperation experience to their Damen colleagues which they in deliver materials and components to the required empower people around you. It is quite traditional in some ways,

(DTC) programme. The POLA project, however, turn used as part of the feedback loop for Damen’s specifi cations. but on the other hand you have everything available to succeed

has taken the DTC concept to the next level by design and safeguard planning and production.

applying simultaneous modular construction on two In recognition of this, Admiral José Antonio Sierra together. It’s all about cooperation and managing diverse groups

continents. This format has already been proved a The three pillars of modular building Rodriguez, Director General of Naval Construction, of stakeholders on each project. It can be very complex.”

success by DSNS in the construction of two SIGMA The success of the POLA project and others like was recently quoted as saying, ”I would like to

10514 PKR frigates for the Indonesian Navy, with it rests on three pillars; process control, global say that the benefi ts that we must recognise are

the transfer of skills enabling the construction of coverage and building strategy. Total process those that the country obtains from acquiring the When asked about recent developments at DEGd, she says, “At

all six modules for any future vessels to take place control at every stage is vital for projects that span technology, developing the infrastructure and

domestically. continents yet depend on real-time coordination. training personnel. This vessel is an extension of our DEGd, everything accelerated dramatically in 2018 due to

Digital platforms for information availability and country, representing Mexico as it travels the world demand and the prospect of building bigger ships. This will take

The excellent cooperation between Damen and the visualisation of progress play an important fl ying its fl ag.”

the Mexican Navy is due in part to the synergy role. Global coverage is all about optimising local us to a new level of complexity and scale, and will result in much

developed through the previous building together yards yet maintaining a fl exible approach so that For Mexico, in Mexico, by Mexicans more International cooperation. Part of this will involve setting

of ten Tenochtitlan class patrol vessels, based on a SIGMA vessel can be built anywhere, and a He has every reason to be proud. This project has

the Damen Stan Patrol 4207, and the logistic supply complete building strategy from the outset ensures been a triumph of cross-border cooperation, and up a detailed engineering branch at Damen Shipyards Mangalia

vessel Isla María Madre, derived from the Damen that everyone knows how they fi t into the overall everyone at Damen and within the Mexican Navy for the big ships. As a result, each and every communication

Fast Crew Supplier 5009 design. These projects picture, what their goals are and when they need to who contributed to its success has a right to share

provided a signifi cant transfer of technology deliver them. in that pride. channel we have is now a hotline. Traditional email is just too

to the Mexican shipyards involved and laid the slow so we have moved to using a range of messaging and video

groundwork for the much larger and more complex The multiplier effect of technology transfers In November 2019, the ARM Reformador will

POLA project. In fact, ARM Reformador will be The transfer of technology is not just about the begin sea trials before going into active service, apps. Conventional reporting up the management line has been

the twelfth vessel that Damen has delivered to the shipyards, although that is important. Despite the representing a critical step in the reformation of the replaced with networking where everyone interacts with each

Mexican Navy. previous cooperation between Damen and the Mexicans Navy’s operational capabilities and the

Mexican Navy, additional training was required at Mexican shipbuilding industry. other in real time on a project, ensuring a free fl ow of information.

As part of the POLA project, the Damen team in ASTIMAR 20 for the specifi c welding techniques This is crucial with big projects. It’s a high energy environment and

Vlissingen in the Netherlands was mirrored by a needed for the hull, and differences regarding

Mexican Navy team embedded alongside them. its working methods were identifi ed and resolved it’s very exciting!”.