Page 73 - Damen Shipyards Group

P. 73

72 VESSEL FOCUS | ASD TUG 2813 73

THE LAMINATED

DAMEN SAFETY GLASS WINDOWS

PROVIDE EFFECTIVE INSULATION

AND BRING DOWN THE REQUIRED

USE OF AIR-CONDITIONING

CAPACITY BY A CONSIDERABLE 50%.

the first thing you encounter is a changing room – forming a cross- To meet Damen’s, and its clients’, goals of increased maritime

over space between the living and working areas. sustainability, the design of the ASD Tug 2813 has once again

gone into every conceivable detail to identify enhancements. “By

“In the accommodation areas we’ve given plenty of thought to crew creating a vessel that functions at the optimum size, less auxiliary

requirements. Their living areas are spacious, in spite of the vessel’s power is required, once again reducing fuel consumption. All of

compact nature, and constructed of durable, waterproof materials. these measures drive down fuel consumption, thereby considerably

Electrical sockets are well spaced to give easy access for charging reducing both the OPEX and emissions.

mobile phones, for example, and each cabin has its own en-suite

facilities.” The vessel also has very low noise and vibration levels, “In the same way, the laminated Damen Safety Glass windows

with COMF-NOISE 3 and COMF-VIB 1 notations, and a comfortable provide effective insulation and bring down the required use of

mess room provides a communal living space with settees, radio air-conditioning capacity by a considerable 50%.” There are also

and TV. options with the vessel that can further extend its environmental

credentials. For instance, it can be supplied with its own sewage

Back on deck, the vessel is prepared to be fitted with Damen’s treatment system and bilge water separator if required.” Another

highly-efficient Render & Recovery Winch. This compact system option is a Marine NO Reduction System, which will ensure that it

X

contributes to the vessel’s spaciousness and facilitates excellent is fully compliant with IMO Tier III regulations.”

views from the wheelhouse. It has no gearbox, no additional

clutches, no water-cooled disc brakes and no different speed/pull This works by injecting urea into the exhaust. This triggers a

settings. This, combined with its control via the ergonomic human- chemical reaction with the gases that reduces the NOx emissions

machine interface, makes for a highly user-friendly operation. by substantially more than the 80% required to comply with the

regulations. The vessel can also be supplied with Bureau Veritas

STRONG, STABLE & SUSTAINABLE Clean Ship Notation or Lloyd’s Eco Notation. The ASD Tug 2813

Where the vessel’s efficiency truly reaches its peak, however, is in offers not only a sustainable performance by today’s standards, but

its sustainability. “By its very nature, such a compact vessel uses also by those of tomorrow. It’s ahead of the game,” he concludes.

significantly less fuel at normal operating speeds and the smooth

hull provides a high level of agility that contributes further to this. You can read more about the ASD Tug 2813’s ability to comply with

When the vessel performs in direct towage it requires less fuel for IMO Tier III regulations on page 26 and about its crew comfort

higher line forces.” credentials on page 92.

“The ASD Tug 2813 has been designed throughout for the best use 2813, the cylindrical fendering absorbs the initial impact, which

of space. This contributes effectively to the goals of both safety is then distributed over the block fenders. This way the average

and efficiency. From a safety perspective, the flush foredeck, which fender pressure never goes over 20 tonnes per square metre.”

is optimised for various towing modes, gives excellent accessibility

to the winches, bollards and fairleads. The aft deck is also open In addition, throughout its tug range Damen uses closed cooling

and clear with no obstructions. In the engine room the spacious, water systems, designed for 35-degree seawater temperatures,

uncluttered theme continues. Here, the engines are mounted on for both the engines and the air-conditioning. “We fit these as

shock absorbers and the piping system fitted in such a way as to standard on our tugs. We see this as an investment in reliability; it

ensure low vibration and noise levels. For maximum safety, all the avoids the risk of pollution and corrosion. And, due to the quality

equipment in the engine room can be controlled from the main of the equipment we use, the closed cooling systems play an

deck. The crew can also monitor the alarms, analyse any problems important role in minimising maintenance requirements.” AZIMUTH STERN DRIVE TUG 2813

and take the necessary action, all from a safe location.

ENERGY, ERGONOMICALLY &

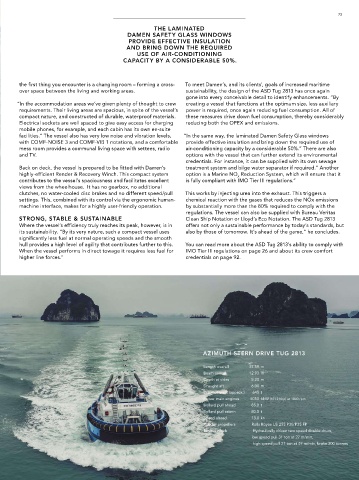

RELIABILITY AS STANDARD ENVIRONMENTALLY EFFICIENT Length overall 27.59 m

12.93 m

Beam overall

Erik says that the fact that the tug is a new design is no barrier to “The ASD Tug 2813 is efficient in every way – starting with the

its claim to reliability. “Although it’s a new design featuring a lot of design process. Damen’s TugSim software allows us to calculate Depth at sides 5.20 m

innovation, the ASD Tug 2813 draws heavily on its proven Damen the escort forces on the towing line and so predict the effects that Draught aft 6.00 m

645 t

Displacement (approx.)

heritage and uses a lot of tried and tested technology,” he asserts. these will have on the performance of a tug. The findings are then

incorporated into the design for optimal efficiency and predictable Power main engines 5050 bkW (6772 bhp) at 1800 rpm

To ensure the reliability of the tug, Damen has taken great care behaviour. “The theme of efficiency continues with the build,” says Bollard pull ahead 85.0 t

Bollard pull astern

80.0 t

to ensure its ease of maintenance. For example, all the steel Erik. “We’ve streamlined this to use the minimal possible number of

parts are well rounded, welding is performed without underlap components, so construction takes less time.” Speed ahead 13.0 kn

Rudder propellers

or undercutting and the bulwark is closed. The fendering has also Towing winch Rolls Royce US 255 P30/P35 FP

Hydraulically driven two speed double drum,

been a point of close attention. “It’s a challenge to design a fender The tug is also an efficient working space. It features a carefully

that will not damage the skin of an assisted vessel that is working at planned layout that aims for smooth working logistics. Starting with low speed pull 31 ton at 27 m/min,

sea with a pushing force of 85 tonnes. The waves make it necessary the uncluttered, spacious decking, every detail has been taken into high speed pull 27 ton at 49 m/min, brake 200 tonnes

for it to absorb a tremendous amount of energy. With the ASD Tug consideration. For example, when you enter the accommodation,