Page 75 - Damen Shipyards Group

P. 75

74 REPAIR & CONVERSION | DESTINATION OF CHOICE 75

DESTINATION

OF CHOICE

FO R T H E M OS T CO M PL E X S O M U C H W O R K , S O L I T T L E T I M E O N T I M E A N D F I T- F O R - P U R P OS E

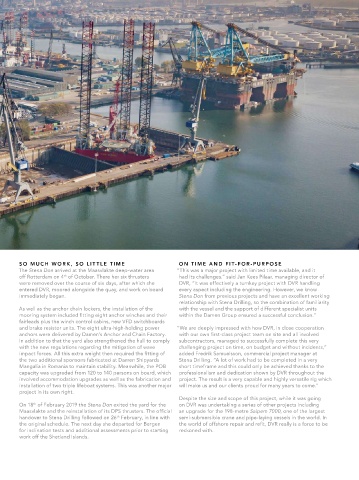

O FFS H O R E PR O JEC T S The Stena Don arrived at the Maasvlakte deep-water area “This was a major project with limited time available, and it

th

had its challenges.” said Jan Kees Pilaar, managing director of

off Rotterdam on 4 of October. There her six thrusters

were removed over the course of six days, after which she DVR, “It was effectively a turnkey project with DVR handling

entered DVR, moored alongside the quay, and work on board every aspect including the engineering. However, we know

immediately began. Stena Don from previous projects and have an excellent working

DA M E N V E R O L M E R OT T E R DA M ( DV R ) I S FA S T A PPR OAC H I N G I T S S E CO N D relationship with Stena Drilling, so the combination of familiarity

A N N I V E R SA R Y O F J O I N I N G T H E DA M E N FA M I LY. I N T H AT S H O R T S PAC E O F T I M E I T As well as the anchor chain lockers, the installation of the with the vessel and the support of different specialist units

mooring system included fitting eight anchor winches and their within the Damen Group ensured a successful conclusion.”

H A S A L R E A DY D E M O NS T R AT E D I T S A B I L I T Y TO TA K E O N T H E L A R G E S T A N D M O S T fairleads plus the winch control cabins, new VFD switchboards

CO M PL E X O F F S H O R E PR O J E C T S T H A N K S B OT H TO I T S I M PR E SS I V E FAC I L I T I E S A N D and brake resistor units. The eight ultra-high-holding power “We are deeply impressed with how DVR, in close cooperation

anchors were delivered by Damen’s Anchor and Chain Factory. with our own first-class project team on site and all involved

I T S M O R E T H A N 6 0 Y E A R S O F S H I P R E PA I R A N D CO N V E R S I O N E X PE R I E N C E . In addition to that the yard also strengthened the hull to comply subcontractors, managed to successfully complete this very

with the new regulations regarding the mitigation of wave challenging project on time, on budget and without incidents,”

impact forces. All this extra weight then required the fitting of added Fredrik Samuelsson, commercial project manager at

S T E N A D O N The refit process in fact started more than three months earlier the two additional sponsons fabricated at Damen Shipyards Stena Drilling. “A lot of work had to be completed in a very

If further proof was needed as to its capabilities, then the recent at the signing of the contract. Work got immediately underway Mangalia in Romania to maintain stability. Meanwhile, the POB short timeframe and this could only be achieved thanks to the

major refit of the drilling rig Stena Don is surely it. The vessel on preparations for the installation of the new, eight-point capacity was upgraded from 120 to 140 persons on board, which professionalism and dedication shown by DVR throughout the

arrived in Rotterdam on the 4 of October 2018 and remained mooring system that was to be the largest single element of the involved accommodation upgrades as well as the fabrication and project. The result is a very capable and highly versatile rig which

th

there for nearly five months undergoing a comprehensive range refit. Engineering began at once followed by the manufacture installation of two triple lifeboat systems. This was another major will make us and our clients proud for many years to come.”

of works to prepare her for her next project, with DVR delivering of various elements of the system including the anchor chain project in its own right.

a complete turnkey package. lockers, and also two sponsons. Weighing 1,200 tonnes in total, Despite the size and scope of this project, while it was going

they were all fabricated at Damen Shipyards Mangalia before On 18 of February 2019 the Stena Don exited the yard for the on DVR was undertaking a series of other projects including

th

The Stena Don, a harsh environment, dynamically positioned, fifth being shipped to Rotterdam ready for installation. Maasvlakte and the reinstallation of its DPS thrusters. The official an upgrade for the 198-metre Saipem 7000, one of the largest

generation semi-submersible drilling rig capable of drilling in handover to Stena Drilling followed on 26 February, in line with semi-submersible crane and pipe-laying vessels in the world. In

th

waters up to 650 metres deep, is owned and operated by Stena The installation of an eight-point mooring system was deemed the original schedule. The next day she departed for Bergen the world of offshore repair and refit, DVR really is a force to be

Drilling. 95.5 metres in length and with a beam of 67 metres, she necessary for her future drilling contracts. The Stena Don already for inclination tests and additional assessments prior to starting reckoned with.

was built by the Kvaerner Warnow Werft Shipyard in Germany in had a DP3 system for maintaining position, but an anchor-based work off the Shetland Islands.

2001 and, following the refit, has accommodation for up to 140 system is more effective in shallow waters and, by not having

personnel. thrusters in continual operation, emissions can be significantly

reduced and substantial savings on fuel costs made.