Page 93 - Damen Shipyards Group

P. 93

92 SAFETY | WELFARE IN THE SPOTLIGHT 93

PUTTING SAFETY AND

WELFARE IN THE SPOTLIGHT

PAR T 1: TUGS

When a new ship is unveiled, it is only logical that a lot of in vibrations, noise, fuel consumption and emissions and penetrating. “This makes the wheelhouse a much safer working safety and ease-of-use has been at the forefront the design

attention is directed at its more technical aspects. These gives the captain a very predictable vessel.” For a tug environment,” he adds. process. For example, there are four computers on board;

are different for every type of vessel that Damen builds. To captain, concentrating hard on the task of assisting an one in the engine room, one on the deck level and two in

put it simply, patrol vessels need to be fast, Shoalbusters incoming container ship, for example, this predictability Because the Damen Safety Glass has a twin-layered the wheelhouse. “This redundancy means that there is no

need to combine shallow draught with bollard pull, and means one thing: safer operations. composition, it means that it is not only safe, but also quiet. need for the crew to go below deck during an operation

dredgers need to have reliable power. The subject of ship “Noise levels are extremely important for both safety and – they can read all the data and operate all the required

design goes so much deeper, however. In fact, the human Moving up to the superstructure, the wheelhouse can be welfare. When sound levels are low, then communication equipment from the deck level. This is a very important

element – namely the safety and well-being of a vessel’s best described as the nerve centre of the tug. Therefore, between the crew and over the radio is a lot easier and there safety issue that the crew do not have to go below deck.”

crew – is a subject that Damen never underestimates. it is paramount to ensure that it is kept out of harm’s way. is less risk of misunderstandings. This is one of the basics

André de Bie, design & proposal engineer Tugs, uses This is achieved by having a high degree of tumblehome. of safety. And in terms of crew welfare, noise levels are also Integration

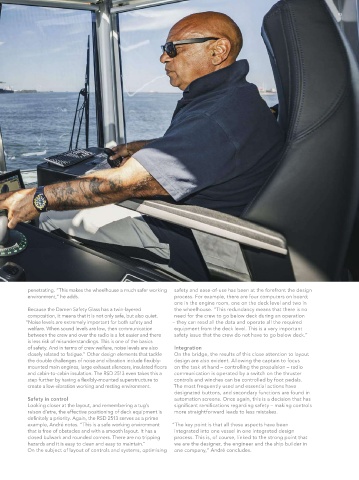

Damen’s range of New Generation Tugs to illustrate this This is the narrowing of the vessel as it rises above the closely related to fatigue.” Other design elements that tackle On the bridge, the results of this close attention to layout

point. waterline. For a tug, the larger the tumblehome, the closer the double challenges of noise and vibration include flexibly- design are also evident. Allowing the captain to focus

it can get to the vessel that it is assisting without the risk mounted main engines, large exhaust silencers, insulated floors on the task at hand – controlling the propulsion – radio

“Of course we have targets for bollard pull and of damage. The lines of sight from the wheelhouse are also and cabin-to-cabin insulation. The RSD 2513 even takes this a communication is operated by a switch on the thruster

performance, but the safety and welfare of the crew very important; the captain should have excellent visibility step further by having a flexibly-mounted superstructure to controls and winches can be controlled by foot pedals.

really is the basis of a good design,” begins André. “From of the deck and also the surroundings. “We have called this create a low-vibration working and resting environment. The most frequently used and essential actions have

the shape of the hull and the layout of the deck, to the the Full Vision Bridge, as a captain must be able to see all designated buttons, and secondary functions are found in

wheelhouse design and the functionality and organisation the key points during manoeuvres.” Safety in control automation screens. Once again, this is a decision that has

of the engine room. Even the colour of the interior. All Looking closer at the layout, and remembering a tug’s significant ramifications regarding safety – making controls

these aspects are integrated into the total design.” Reducing noise and vibration raison d’etre, the effective positioning of deck equipment is more straightforward leads to less mistakes.

Damen has also paid special attention to the glass used in definitely a priority. Again, the RSD 2513 serves as a prime

Full vision the wheelhouse. “One of the biggest dangers a tug faces is example, André notes. “This is a safe working environment “The key point is that all these aspects have been

Taking the hull as the starting point, the first thing you the towline snapping – this could easily break a window. We that is free of obstacles and with a smooth layout. It has a integrated into one vessel in one integrated design

notice is its round-bilged form. “This is the most efficient have developed the Damen Safety Glass to prevent this.” closed bulwark and rounded corners. There are no tripping process. This is, of course, linked to the strong point that

shape; an optimised hull can deliver the same amount of The glass to which André is referring is a shatterproof glass hazards and it is easy to clean and easy to maintain.” we are the designer, the engineer and the ship builder in

performance with less power. This leads to a reduction that can withstand multiple impact blows before actually On the subject of layout of controls and systems, optimising one company,” André concludes.