Page 22 - Hempflax Nature wins!!

P. 22

Nature wins!

HempFlax hemp cultivation

Separating fibre from wood

Pure premium quality

An important development in the modern processing of hemp was the design of a machine

to separate the bast fibre from the stalks’ wood core through a process called

‘decortication.’ The first decortication line, developed and installed in the HempFlax factory

was 77 metres long. A few years later, a second decortication line of 55 metres was built,

which produces an even finer fibre.

In 2009, HempFlax managed to merge both processes together into one single efficient

production line. By investing decades of experience into this production line, employees

have managed to ensure that the fibres of HempFlax are regarded internationally as being

of premium quality. No commercially available production line achieves purity above the

98% of HempFlax.

The machines currently process 4

tons of hemp straw per hour. The

HempFlax process line not only

separates the bark fibre from the

wood, but also the remaining leaves,

seeds and substance. These five raw

materials form the basis for all the

organic products that HempFlax

currently puts on the market.

HempFlax stands for quality,

recognised and guaranteed by the

implementation of ISO 9001.

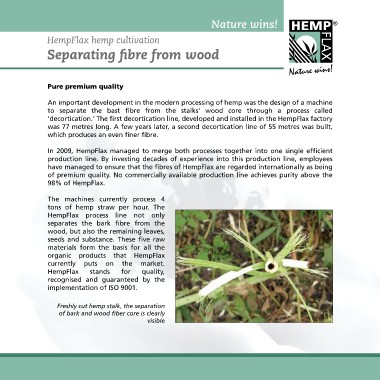

Freshly cut hemp stalk, the separation

of bark and wood fiber core is clearly

visible