Page 117 - Damen Shipyards Group

P. 117

116 REPAIR & CONVERSION | TARMAC MARINE’S AGGREGATE DREDGERS 117

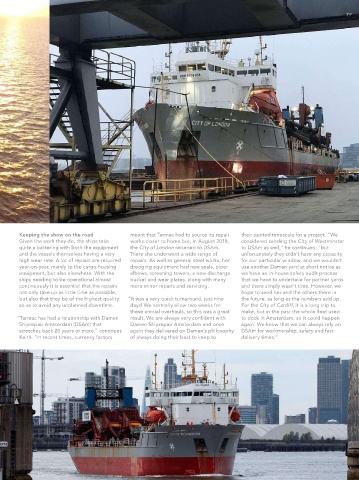

Keeping the show on the road meant that Tarmac had to source its repair their quoted timescale for a project. “We

In the world of dredging, there DREDGING FOR Given the work they do, the ships take works closer to home but, in August 2018, considered sending the City of Westminster

quite a battering with both the equipment

the City of London returned to DSAm.

to DSAm as well,” he continued, “but

are few sectors as challenging as and the vessels themselves having a very There she underwent a wide range of unfortunately they didn’t have any capacity

high wear rate. A lot of repairs are required

repairs. As well as general steel works, her

aggregates. While sand is highly year-on-year, mainly to the cargo housing dredging equipment had new seals, piper for our particular window, and we wouldn’t

use another Damen yard at short notice as

abrasive, gravel is even more of a AGGREGATES equipment, but also elsewhere. With the elbows, screening towers, a new discharge we have an in-house safety audit process

challenge, being dense, irregular ships needing to be operational almost bucket and wear plates, along with many that we have to undertake for partner yards

continuously it is essential that the repairs

and there simply wasn’t time. However, we

more minor repairs and servicing.

in shape and unforgiving when it not only take up as little time as possible, hope to send her and the others there in

but also that they be of the highest quality

comes into contact with decks, hulls A TOUGH BUSINESS so as to avoid any unplanned downtime. “It was a very quick turnaround, just nine the future, as long as the numbers add up.

days! We normally allow two weeks for

For the City of Cardiff, it is a long trip to

and equipment. Bringing it up from these annual overhauls, so this was a great make, but in the past the whole fleet used

the seabed, depositing it in the Tarmac Marine is a subsidiary of Tarmac, “The City of Chichester and the City of “Tarmac has had a relationship with Damen result. We are always very confident with to dock in Amsterdam, so it could happen

Damen Shiprepair Amsterdam and once

hold and then off-loading it once the UK’s largest supplier of building Cardiff are very similar to each other Shiprepair Amsterdam (DSAm) that again they delivered on Damen’s philosophy again. We know that we can always rely on

DSAm for workmanship, safety and fast

stretches back 20 years or more,” continues

back at the terminal takes a toll on a materials with a history that dates back in size and design. 72 metres by 15 Keith. “In recent times, currency factors of always doing their best to keep to delivery times.”

metres, they can each carry 1,418m³ of

over 150 years. With over 120 quarries in

vessel, yet they can ill-afford time off its portfolio producing every conceivable material and were built in 1997. The City

work. Aggregates are a low-margin type of aggregate it is not surprising that, of Chichester operates in the English

product, and the dredgers that do even within the company, not everyone Channel, serving the south coast of

is aware that it also operates four trailing

England, while the City of Cardiff extracts

it need to work almost constantly to suction hopper dredgers. sand on the UK west coast and delivers it

make a return. to wharves in the Bristol Channel and in

“The City of London and the City of the North West.

Westminster are sister ships,” explains

Keith Marshman, Marine Fleet Manager All the gravel is used mainly in the

for Tarmac. “They were delivered in 1989 production of concrete and over 90% of

and 1990 respectively. 100 metres in the total aggregate that the four vessels

length and with a deadweight tonnage of together extract each year is used

5,989 they are capable of dredging down internally within the group.

to 40 metres. They operate in the North

Sea off the coast of England and land

their cargoes within Tarmac’s network of

Thames wharves to supply London and its

surrounding region