Page 35 - Damen Shipyards Group

P. 35

34 SUSTAINABILITY SPECIAL 35

Arriva requested more body in the fender

construction and more daylight in the cabin FULL INTEGRATION

and wheelhouse. Damen added stronger Completing the project wasn’t as simple as putting boats in the water – meeting

fenders, large windows, and additional skylights the tender’s criteria for an environmentally-friendly source of propulsion for the

to the ferries. The vessels need to be highly vessels raised a number of complex variables that required investigation. Martin

manoeuvrable, able to resist high winds and icy Verstraaten, Damen Sales Manager, took his team to Copenhagen to get a good

waters, so they have a low superstructure to understanding of the full scope of the project. “In Copenhagen, we conducted

minimise wind resistance and a strong hull, with an extensive safety and reliability investigation to get an exact understanding of

ice strengthening in the bow. the conditions and requirements of the project. We made sure we were aware of

every component and contingency.”

The cabin is slightly raised and features

generous windows fore and aft, and together Examples of these components include the floating jetties that serve each stop

with CCTV feeds from strategic points on the on the ferry route; new vessels supplied to operate the route had to be compliant

vessel, supplies optimal visibility for the captain with these jetties and had to account for all aspects of accessibility and safety. A

when manoeuvring. Inside the wheelhouse, the more aesthetic component was Damen’s careful consideration of the passenger

dashboard is fitted with an optimised human experience: Damen fitted large windows along the vessels’ sides, and rows of

machine interface (HMI), offering minimum skylights in the roof, in order to allow plenty of daylight to enter the passenger

distraction while providing the exact information hold. Each boat features unique interior décor, including an image of a local

needed to pilot the vessel with maximum landmark, adding to its individual personality.

efficiency.

Given the demands of its operation, each ferry

carries two drivetrains to provide a good level of The hulls were designed to achieve

redundancy should any unexpected problems occur.

low resistance in order to save on

the energy required from the battery

packs and the propeller was optimised

for electrical propulsion using software

that measures the torque of the engine

and the speed of the propeller.

MOVING FORWARD

Propulsion was a major factor in the design of the vessels. Movia requested a

cleaner, greener use of energy from its ferry service, and Damen had a number

of options available. Engineers considered biodiesel engines, hybrid vessels with

generators on board, and full electric solutions, ultimately deciding full electric In the fully-electric solution, power comes from

was the optimal choice for the twelve year operation of the ferries, based on battery packs on board. Bastiaan Vink, design

several factors. and proposal engineer at Damen, was heavily

involved in the process. “Choosing the battery

This zero emissions, fully electric solution is quiet in operation and is much more packs depends on multiple variables such as

maintenance-friendly than a diesel option. Combustion engines contain a lot the length of route and time in operation, the

more mechanical parts that can fail, and the oil used for lubrication of these torque of the engine and the average weight of

moving parts makes the system very dirty in comparison with an electric motor. the vessels under operational conditions.

At the same time, Damen investigated the shore solutions for supply of electric “We used computational fluid dynamics (CFD)

power. Movia’s stipulations required at least 60% of the power to be drawn from in the design of the hulls to ascertain the levels

a green source, so Damen ensured this shore option was available for recharging of resistance they would face in the water

purposes. and the propulsion required to overcome the

resistance to a highly mobile and manoeuvrable

The next decision to make was how often the vessels could charge their power degree. The hulls were designed to achieve

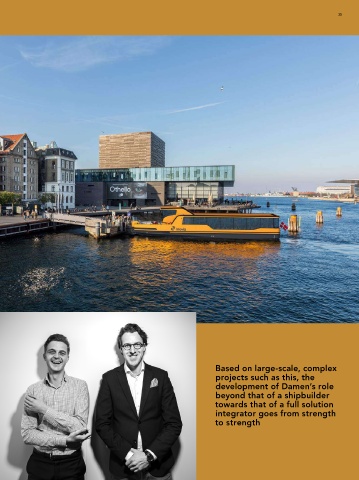

supply – how could the ferries operate all day on a minimal battery pack and low resistance in order to save on the energy Based on large-scale, complex

recharge without disrupting their schedule? required from the battery packs and the

propeller was optimised for electrical propulsion projects such as this, the

To answer this question, Damen Civil – another branch of Damen’s complete using software that measures the torque of the development of Damen’s role

service provision – investigated full civil solutions such as accessibility to the local engine and the speed of the propeller.” beyond that of a shipbuilder

grid, the regulations surrounding civil power supply, and the practical limitations

of the jetties as potential charging points. The ferry route takes one hour to This foresight helps to minimise the number of towards that of a full solution

complete, and at each end there is a small window in which to prepare for the battery packs the vessel needs to carry on its integrator goes from strength

beginning of another route. Damen saw this as a window of opportunity to take route, which in turn saves on weight and allows

advantage of a fast-charging system. it to operate more efficiently, also saving on cost. to strength

Design and proposal engineer Bastiaan Vink explains the logic; “By charging

every hour, the ferries replenish their relatively small battery pack at the

beginning and end of each route. The combination of a fast-charging system and

a small battery pack allows them to recharge in as little as seven minutes without

disrupting their schedule.”