Page 36 - Damen Shipyards Group

P. 36

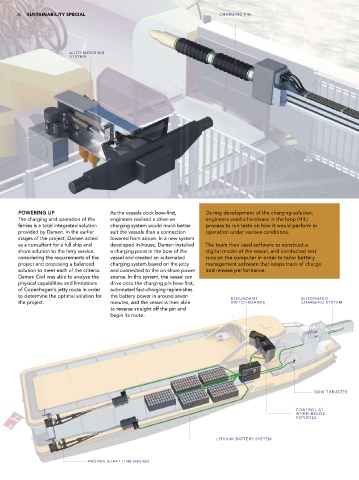

36 SUSTAINABILITY SPECIAL CHARGING PIN TRANSFORMER IN THE WORKS 37

At the point at which construction of the fi ve vessels was

almost ready to begin, a change in requirements was

announced. Movia wanted to extend its ferry route by an

additional four stops, increasing the length of the route

by roughly 50% and taking the ferries into Copenhagen’s

AUTO-MOORING port area,” explains sales manager Martin. As part of the

SYSTEM

expansion, two additional vessels were requested from

Damen.

The route extension signifi cantly impacted the scope of the

project, affecting the duration of each route, the power

demands on each vessel, and the charging facilities installed

to supply that power. We investigated ten scenarios for a fully-

integrated solution to the route extension, ultimately deciding

the project expansion required an innovative charging solution

to be installed at the port area terminal,” Martin states.

Stronger weather conditions, producing a larger wave impact

in the port area, affects movement of the ferries at the jetty,

which must therefore be secured in order to access the

charging system. Damen’s solution to this challenge was to

develop an auto-mooring system that controls the motion

of the vessel and secures it to the jetty as its batteries are

charging. This solution largely increases the safety around the

integral system.

The auto-mooring system was designed and engineered

in collaboration with Damen’s Winch Department. The

development of this mechanical system required the

measurement of wave dynamics and calculation of the forces

POWERING UP As the vessels dock bow-fi rst, During development of the charging solution, involved in vessel turbulence in order to produce a secure

The charging and operation of the engineers realised a drive-on engineers used a hardware in the loop (HIL) mechanism. With no pre-existing solution available on the

ferries is a total integrated solution charging system would much better process to run tests on how it would perform in market, the bespoke system was developed in-house by

provided by Damen. In the earlier suit the vessels than a connection operation under various conditions. Damen and is currently being adapted for use in similar

operation under various conditions.

stages of the project, Damen acted lowered from above. In a new system electrical propulsion projects with future clients.

as a consultant for a full ship and developed in-house, Damen installed The team then used software to construct a

The team then used software to construct a

digital model of the vessel, and conducted test

shore solution to the ferry service, a charging point in the bow of the digital model of the vessel, and conducted test In addition to the vessel security, Damen adapted the

runs on the computer in order to tailor battery

considering the requirements of the vessel and created an automated runs on the computer in order to tailor battery charging process to cope with the higher demands of an

management software that keeps track of charge

project and proposing a balanced charging system based on the jetty management software that keeps track of charge extended route. Damen increased the battery charging

and release performance.

solution to meet each of the criteria. and connected to the on-shore power and release performance. capacity from 450kW to 600kW per charger, to supply each

Damen Civil was able to analyse the source. In this system, the vessel can vessel with the power it needs to complete the route –

physical capabilities and limitations drive onto the charging pin bow-fi rst, including in the case of one charging point being temporarily

of Copenhagen’s jetty route in order automated fast-charging replenishes disabled – accounting for further redundancy in the system.

to determine the optimal solution for the battery power in around seven REDUNDANT AUTOMATED

the project. minutes, and the vessel is then able SWITCHBOARDS CHARGING SYSTEM Damen will deliver the fi rst fi ve vessels according to contract, and

to reverse straight off the pin and the two additional vessels will be ready for delivery in May 2020.

begin its route. The charging point system is close to completion, and Damen

looks forward to the beginning of its operation. Proud of the

interdepartmental collaboration displayed throughout, Damen

regards this project as an excellent showcase of its engineers’

entrepreneurial capacity and vision. “Based on large-scale,

complex projects such as this, the development of Damen’s

role beyond that of a shipbuilder towards that of a full solution

integrator goes from strength to strength,” Martin concludes.

LOOKING BACK TO THE FUTURE

BOW THRUSTER To enable operators to track and analyse the

performance of this complex system in action, Damen

can install remote monitoring capabilities on all of the

CONTROL AT vessels, informed by a network of on-board sensors.

WHEELHOUSE

CONSOLE Damen’s Remote Monitoring Department is able to

set up personalised dashboards for every employee,

tracking a variety of factors from battery lifecycle to

sailing patterns to swell dynamics. Through access to

LITHIUM BATTERY SYSTEM

this data, clients can track the performance of their

vessels. Similarly, Damen is able to use this remote

monitoring capability to identify potential areas for

PROVEN SHAFT LINE DESIGN improvement and use the data to inform future projects.